The terrifying incident over Oregon late last week still remains largely unresolved. However, I’m going to provide an update on AS1282 as new information has shed light on what potentially caused the frightening yet lucky incident.

As we all know, Alaska Airlines Flight 1282 from Portland, Oregon, to Ontario, California, experienced an uncontrolled decompression event on Friday, January 5. The flight was operated by N704AL, a nearly factory-fresh Boeing 737 MAX 9. The youth of the aircraft made such an event seem implausible. However, very quickly, it became clear that the decompression was caused by a part failure rather than a fuselage compromise due to an uncontained engine failure or metal fatigue.

With subsequent inspections by Alaska Airlines and United Airlines of their MAX 9 fleets, we now have a good idea of what happened, though the root cause remains a mystery.

An Update on AS1282

Before we get into the update on AS1282, I want to go over what happened a bit more. You see, in my prior post, I stated that “part of the fuselage blew off.” As we’ve come to learn, that’s not true. Instead, the door plug on the port (left) side of the aircraft came loose and blew out of the fuselage opening, triggering the uncontrolled decompression event.

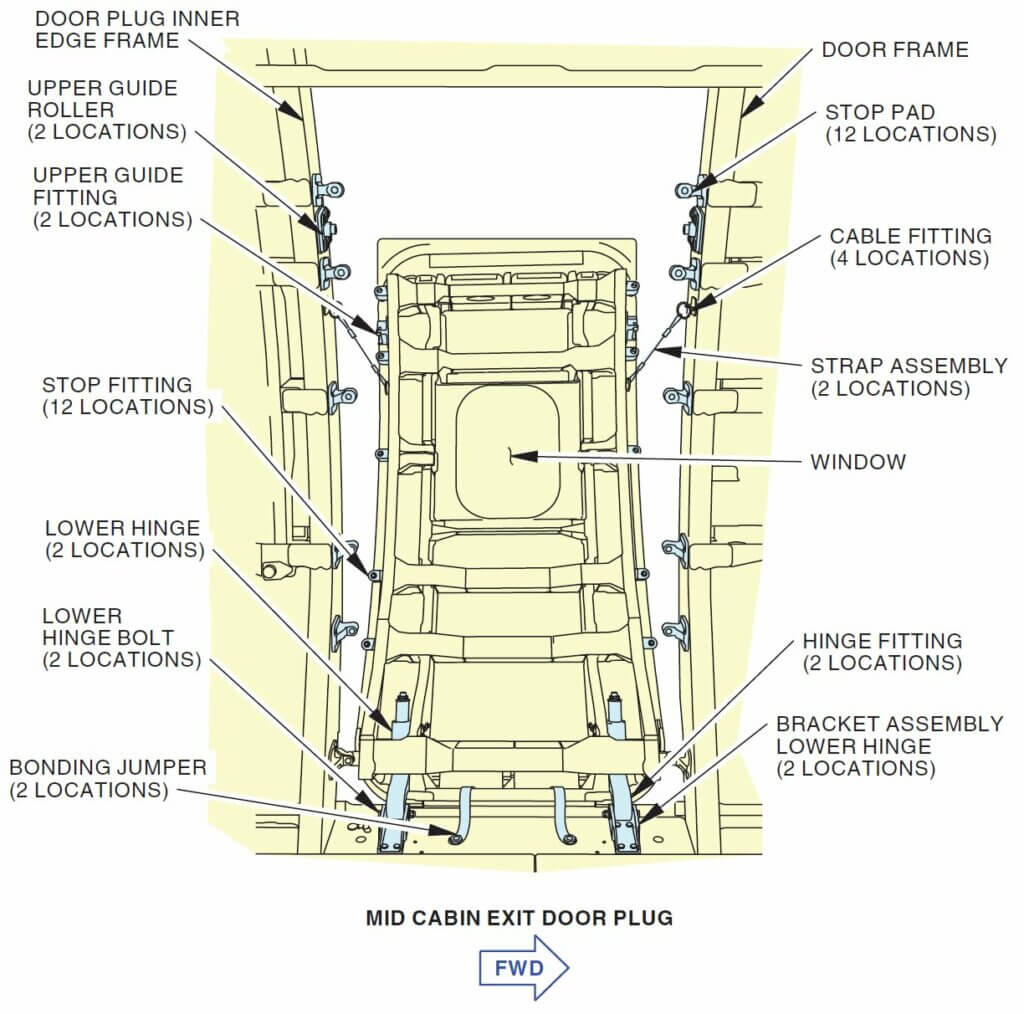

What the heck is a door plug, you ask? Well, the Boeing 737 MAX 9 and even the 737-900 are sold in two different configurations – standard and high-density. In its standard configuration, the 737-9/900 has four full-size doors plus four emergency exits over the wing. However, to comply with emergency egress regulations, an additional set of doors is required for denser configurations with 189 to 220 seats. These configs are often used by low-cost carriers like Lion Air.

For airlines that don’t need these additional doors, such as Alaska and. United, a door plug is installed in place of an actual door. From the inside, you wouldn’t know a door could be there, as a standard wall panel and window fill the space. However, from the outside, you can see an outline of where the door plug is.

Now, a door plug shouldn’t be confused with a plug door. Plug doors are what the normal doors on an aircraft are called. Why? Because the cabin pressure at altitude keeps these doors sealed shut and also makes them impossible to open when the cabin pressure is higher than the atmospheric pressure outside. On the other hand, a door plug, as explained above, fills a hole in the fuselage where a plug door could be installed. Go it?

Door Plug Came Loose

With the explanation of what a door plug is out of the way, I’d like to get into our update on AS1282. Specifically, it was that a door plug came loose during the flight, which caused the uncontrolled decompression event. No fuselage damage caused the incident – just a part filling an opening that was meant to be there. Naturally, the question now turns to why and how that part – the door plug – came out. And that’s what the NTSB is still trying to figure out.

You see, a door plug operates similarly to a standard plug door on Airbus aircraft and Boeing 777s. In these cases, stop fittings allow the cabin pressure to push the door against the fuselage to seal it without the door (or door plug) from flying out. Whereas, on the 737 and other Boeing aircraft, the (boarding) doors themselves seal against the fuselage when the cabin is pressurized.

For the 737’s door plug specifically, the plug must be slid upwards to disengage them from the stop fittings. Four bolts are supposed to stop this upward movement.

According to the latest reports from the NTSB, these four bolts are missing. Now, it’s important to note that we don’t know if the bolts went missing during the decompression event or if they were never there to begin with. NTSB officials state that determining this will take quite some time – up to a year if the bolts aren’t located. However, there are indicators that the bolts may have been there but weren’t properly installed.

The NTSB reports that the guide tracks for the two upper bolts are damaged, suggesting the bolts came loose and were ripped out.

United and Alaska Find Loose Bolts

This next portion of my update on AS1282 was actually reported before the NTSB announced the above findings. During preliminary inspections of their Boeing 737 MAX 9 fleets, both United and Alaska found instances in which the four offending bolts in AS1282 were loose. While not conclusive evidence, this does further support the theory that bolts were present on N704AL but were probably improperly installed. This finding also points to a manufacturing error rather than an engineering issue or materials defect.

Fail Light Played No Role

Circling back again in my update on AS1282, the NTSB reports that the pressurization failure light that came on three times in the month leading up to the incident likely played no role in the depressurization. They state that after examining maintenance logs and aircraft systems, the triple-redundant system functioned as it was supposed to and that the warning light was faulty.

This finding confirms what I believed all along – Alaska’s decision to remove N704AL from trans-Pacific was purely precautionary and didn’t indicate a potential safety issue with the aircraft, as some media outlets have alluded to.

Update on AS1282, Final Thoughts

Suffice to say, this isn’t going to be my last update on AS1282. That said, the timeline from here on out gets a bit murky. The NTSB still needs to find the missing bolts, and if they can’t, they’ll have to rely on materials analysis, among other things, to figure out what happened. In the meantime, Boeing and the FAA will work on processes and procedures to get these birds back into the air ASAP. 171 737 MAX 9 jets remain grounded, causing upwards of 110 to 150 cancelations per day at Alaska alone.

Whatever the case, Boeing will want to proceed cautiously to not further harm what’s already a beleaguered program. Even though I don’t think the MAX is an inherently dangerous aircraft – most of the general public doesn’t understand why, though.

Of course, this issue may not be exclusively Boeing’s. We still don’t know where the failure point occurred. Was the engineering spec for the torque on the bolt incorrect? That would certainly be a Boeing issue. Did Spirit AeroSystems incorrectly torque the bolts? The former Boeing subsidiary actually builds the bulk of the fuselage, including the door plug. If so, it’s partly Spirit’s fault and partly Boeing’s for not conducting proper QC before installing the interior panel.

Again, it’s too early to draw concrete conclusions. That said, it does seem that Alaska played no role in this unfortunate circumstance and that Boeing and, perhaps, Spirit Aerosystems are to blame. However, as the NTSB has stated, we must wait for them to conclude their investigation before we point fingers. The important thing is that no one got seriously injured or worse, we have a pretty good idea what the problem is, and it looks like we should be able to get a fix soon.